Across the spectrum of home improvement projects, from winging it with a roll of duct tape to hiring a licensed contractor, there’s an expanding middle ground of semi-complex projects that people want to do on their own. Some, like hanging shelves, are simple. Others, like installing an accent wall or repairing damaged baseboards, require a little more know-how. But even these projects are tackled by relative home improvement newbies, and social media is full of newbies documenting DIY home improvement projects and decorating, racking up tens of millions of views along the way.

The dirty secret behind these viral videos is that even if the person doing the project doesn’t have a lot of experience, they definitely have the tools for the job—tools that most newbies either don’t have, can’t afford, or can’t squeeze in. their small apartments. So, while a 30-second video of a bench change might be manageable, it’s impossible to do without enough equipment.

Dremel, the brand known for its craft-focused rotary tools, has a new line of affordable and compact tools designed specifically for DIY home improvement beginners. Reverse-engineered by analyzing the steps involved in completing hundreds of the most common home DIY projects, Dremel’s new Blueprint system of compact tools aims to enable users to complete projects with as few tools as possible.

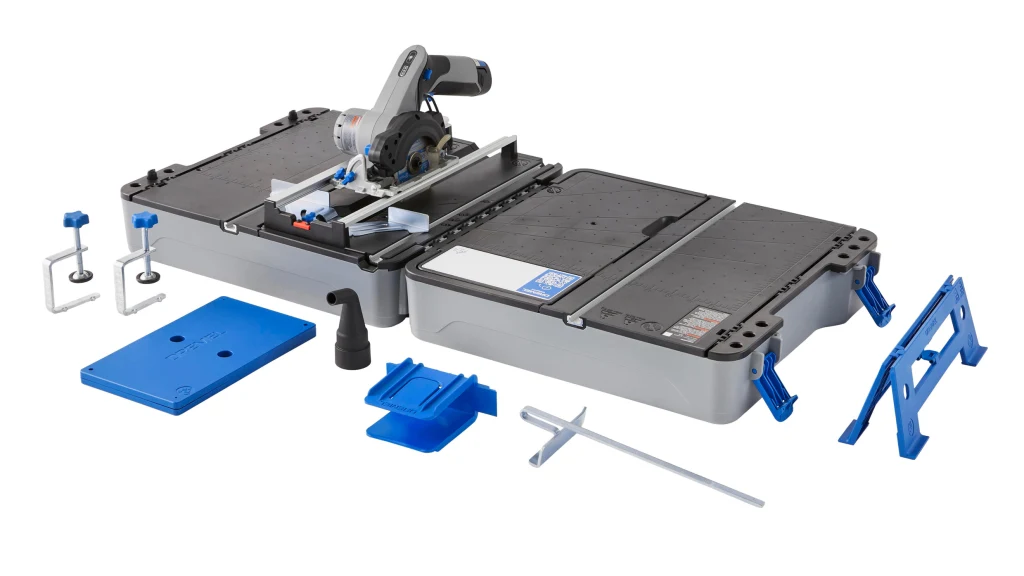

The first two tools in the Blueprint line, available now, are a $99 hand drill with a built-in cord locator and laser level, and an amazingly compact $149 portable saw station with a battery-operated miniature circular saw. Like hyper-optimized contractor equipment, these tools pack functionality into small packages that don’t require a workshop’s worth of space to store.

Like a miter saw, but less scary

The idea for these tools came from seeing how popular DIY home improvement has become on social media, but also how misleading some of these videos can be. Jeremy Rubens, Dremel’s business innovation manager, says he’s come across too many videos of DIY influencers advising their followers to invest in gear that isn’t meant for beginners. A recurring suggestion is the miter saw, a large tabletop machine with a 10-inch blade most commonly seen on construction sites when making two-by-four slices. “These are really big tools that I would never recommend a beginner buy,” says Rubens. “It was a bit of a spark to say, how can we do this better? How do we actually build tools for these people who want to be creative and do basic projects, but don’t have to have all these crazy professional tools?”

Dremel’s product team took a deep dive into what beginners do with their tools and how those projects can be better managed. Rubens, along with Dremel global product director Saad Alam, began an analysis of the most common DIY projects around a home or apartment, encountering everything from hanging a gallery of frames to renovating cabinets and building headboards. For them, DIYers created video diaries of their projects, recording what they saw step by step. The Dremel team then broke down each project into nine key steps and identified the tools used in the critical parts of each project. What they found were a lot of cutters—splitting boards in half, slicing long pieces of wood into narrower strips, sawing angles. “The jobs are all the same,” says Alam.

A miter saw is a type of tool that many projects need. But with its large blade, large size, and overall danger, a miter saw is a tool that most beginners should not use.

“The sending saw is made around two to four [inch] capacity, so it has a large blade. And we realized that many of these projects are actually done with some kind of wood. A lot of it has to do with decorating and decorating, taking furniture and putting accent pieces around it, or taking Ikea furniture and doing Ikea hacks,” says Rubens.

“People don’t really want to deal with giant saw blades,” Alam adds. “So the focus was: how do we design them from an industrial design perspective to be more accessible and actually fit in the hands of different users and genders.”

Compact instrument form factor

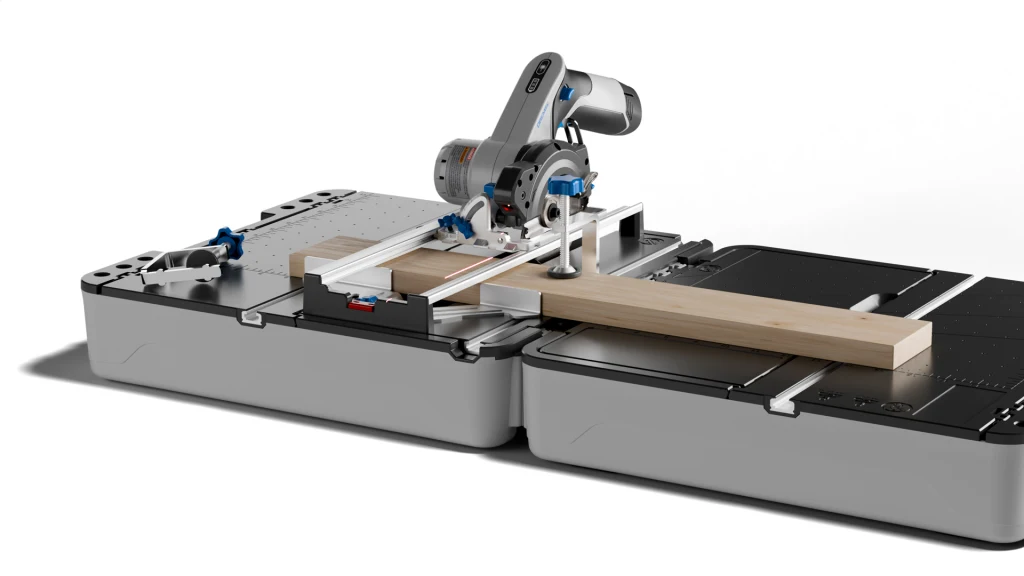

The result is Blueprint, a new line of compact Dremel tools. One is a kind of miniature circular saw, with a blade only 3 and three-quarters in diameter that can cut a standard 1-inch board straight through. The saw is accompanied by an expandable box that doubles as a sawing station, allowing frame and laser-controlled straight cuts, diagonal miters and bevels. It can also be used to cut longer trees by detaching the saw from the station and clamping it to the guide.

Using the Blueprint saw station provided by Dremel, I found each of these cuts to be easy to make and less intimidating than starting up a larger saw. On a recent frosty winter day, sitting in my laundry room, I was able to use the saw, its station, and its guides and clamps to cut several 1-inch boards and split the plywood into several pieces. With a 12-volt battery, the saw isn’t a heavy truck, and it experienced a bit of kickback going through some of the final cuts, but eventually it held its own. One limitation is that the blade is not long enough to perform a full 45-degree bevel cut on a nominal 1-inch board, which would be useful, for example, for sawing wood to realign boards around a corner.

Another disadvantage is that the saw cannot cut two to four at a time; The board must be cut once, turned over, and then cut again. “Unless you’re framing a house where you need 100 two-by-fours, that’s good enough,” Alam says. “It will get you through the draft.”

The Blueprint system’s focus on smaller home improvement and home decoration projects means it doesn’t need to boast about its power, and most importantly, the size of a typical tool. Rubens says Dremel’s industrial designers worked on prototype after prototype to shrink the size, making the system small enough for people who live in apartments or condos or don’t have workshop space in a basement or garage.

This is evident in the Blueprint multi-drill, a scaled-down version of a standard power drill that looks more like the tip of a garden hose than the pistol-shaped drills of professional workshops. An additional guard on the front of the handle appears to be some kind of finger guard, but actually houses a built-in stud finder that speeds up the tool’s general use, such as hanging frames or shelves. “A lot of work went into figuring out how to stack this elbow gun forward without getting in the way,” says Rubens.

Dremel’s research into common DIY projects helps you determine which tools can do double or triple duty, tackling key elements of a project without spending time changing tools or going back to the utility closet to find another piece of equipment. “We don’t expect our users to buy a tool that does just one thing,” Rubens said.

Besides the multi-nose and saw station, other tools are coming soon, though Dremel declined to identify them. The product team’s approach is to narrow down the tasks that people need to perform most often and then build a toolkit that matches most of those needs. “The goal for us is to have a platform of about six to eight core products that can handle hundreds of different DIY projects,” Alam said. “We joke that we’re a power tool company that wants to sell you the least amount of tools, it’s weird.”