In the end Fast company Columns shared my reasons to produce my electric trucks in the United States. Shooting near North America has been a higher priority for the current tariff change and shipping complexity for several years.

However, in the United States, there were 292,825 factories since 2021. More than 846 people or more people work. Some of them are customers of the engineering company, and our existing factories are a number of seats to the complexity of a refund to US production. Expensive and long while building a new factory, the responsibilities of these companies are still difficult.

There are good reasons to make sliding as soon as possible. The higher or faster response period and chain violations to pass to the production of most or fully in the United States, as well as a higher resistance to the protection of tariff change and geopolitical change.

But if you are early in this time, I am my recommendation for the passage:

- Determine the priority rating for the processing and raw material you have passed to the country of domestic and North American source. Provide the highest rating in categories, including defense, high-value items (such as steel, aluminum and rare minerals, etc.) and consumer security items (eg pharmaceutical components, etc.).

- Be more strategic in the naval suppliers you continue to use for a production of more than developed and more geographical friendships for manufacturing and more geographical friendships such as Mexico and Argentina.

- Lithium, red mud, magnesium, etc. Use government-supported capital to produce minerals and metals.

- Go to domestic suppliers for primary materials like steel, aluminum, cement and plastic, outside high-ranking product categories. In the same way, reduce the offshore of technical workers, as well as reducing raw materials and possible raw materials.

- Use all possible means to be independent with solar production, micro-grids and nuclear power generation.

- Imagine creating a 4-year completion bonus for military veterinarians. Hire vets when large employees and entrepreneurs are possible to do.

In the same way, we can press for the best support for future policy changes:

- In addition to creating new vehicles in the United States, as well as automated cargo transit.

- Transform plans for more attractive loans, discounts and grants, as well as taxes for tax-free status for intellectual property, transforming plans for tax-exempt status.

- Imagine energy benefits to American manufacturers and distributors to provide America’s manufacturer more efficient and viable.

- Create a policy to enter the price of the marine staff in tariff calculations. Sugar, avocados, bananas, etc. Expand trade connections with the Caribbean for products such as.

- Avoid or even ban on the external property of the food supply chain.

- Create fair competition for government contract.

- Remove health supplements and homeopathic drug taxes to promote a healthy workforce.

Although this does not expect it easily, these policy changes are related to successful change. In general, we need larger scale, lower costs and more automated and simplified mechanisms for product production. These issues are as equally important as the raw materials we require in my experience. We need growing support to support niche production. In my opinion, we will also sign and land (especially in the West; the existing land that has existing land existing lands).

I believe that we need better education, self-confidence, health and incentive structures to get employees of America, entrepreneurs and America. Who is my?

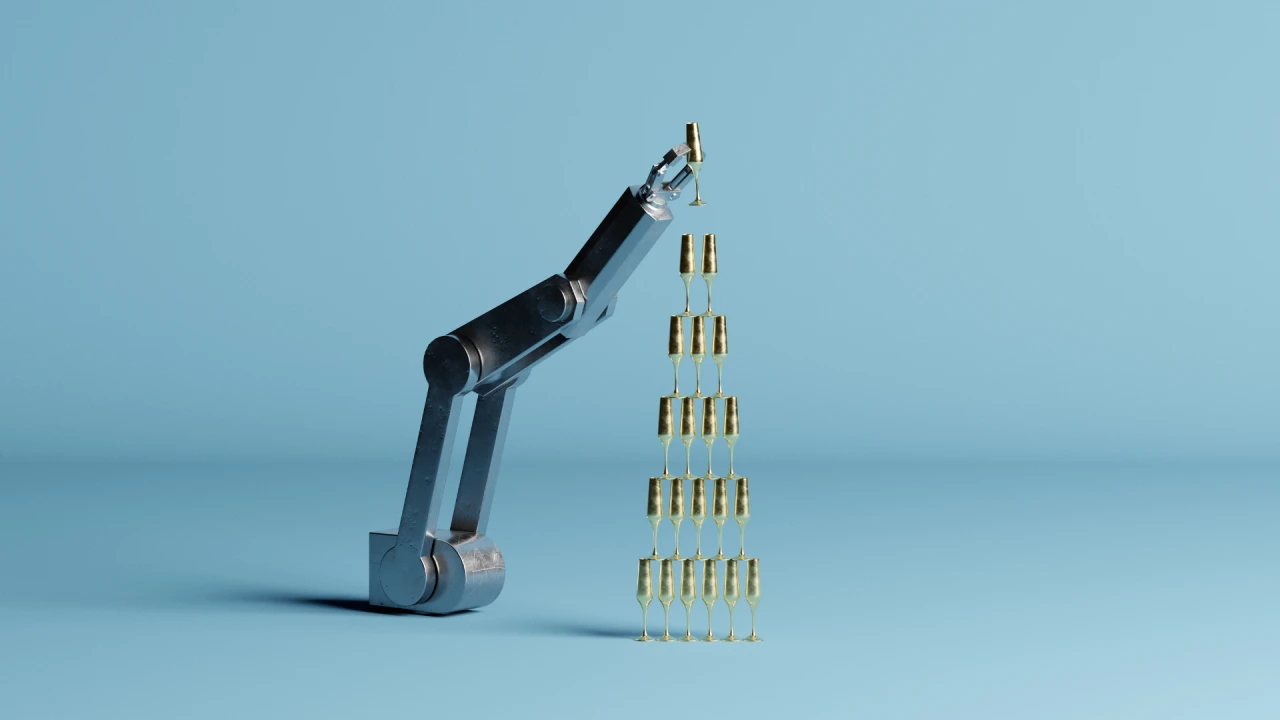

Matthew Chang is a founder partner Chang robotics.